Comprehensive Guide to Fresh Concrete Tests

Fresh concrete tests play a crucial role in ensuring the quality, workability, and durability of concrete mixtures. These tests help construction professionals assess the properties of freshly mixed concrete, allowing adjustments to be made if necessary before the concrete sets. Let's dive into various types of fresh concrete tests and their significance:

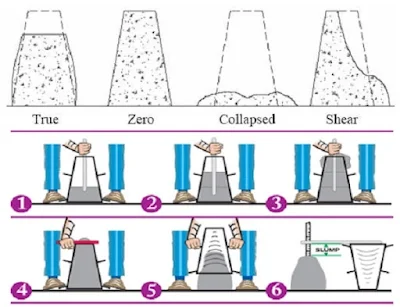

Slump Test

The slump test measures the consistency and workability of concrete. A cone-shaped mold is filled with fresh concrete, compacted, and then removed. The change in height of the concrete's slump indicates its workability. This test helps determine if the concrete has the desired fluidity for proper placement.

Method:

A slump cone is placed on a smooth, flat surface.

The cone is filled with freshly mixed concrete in three layers, each compacted with a rod.

After the cone is filled, the mold is lifted vertically upward, allowing the concrete to settle and spread.

The difference in height between the original height of the cone and the final height of the concrete slump is measured to determine the slump value.

Flow Table Test

The flow table test assesses the flowability and cohesion of self-compacting concrete. Fresh concrete is placed on a flow table, and the number of times it flows within a specific diameter is measured. This test is particularly useful for assessing the consistency of self-leveling concrete mixes.

Method:

Freshly mixed self-compacting concrete is placed on a flow table.

The flow table is raised and dropped multiple times, causing the concrete to flow and spread.

The diameter of the concrete spread is measured, providing an indication of the concrete's flowability and workability.

Air Content Test

The air content test gauges the volume of air voids in fresh concrete. Excessive air content can weaken the concrete, while insufficient air content may lead to durability issues due to freezing and thawing cycles. The pressure method and the volumetric method are two common techniques used to determine air content.

Method:

The pressure method involves placing a known volume of concrete in a container. Pressure is applied to the container, which compresses the air voids in the concrete. The reduction in volume is used to calculate the air content.

The volumetric method utilizes specialized equipment that determines the air content by measuring the volume of air voids in the concrete sample.

Temperature Test

The temperature test measures the temperature of fresh concrete upon mixing. Elevated temperatures can accelerate setting and hydration, impacting the overall strength development. Monitoring the temperature helps prevent issues like thermal cracking and ensures optimal curing conditions.

Method:

Temperature tests are typically conducted by inserting a temperature probe into freshly mixed concrete immediately after mixing.

The temperature reading is taken and recorded. Monitoring the concrete's temperature is important to assess its potential for setting time acceleration or retardation.

Unit Weight Test

The unit weight test determines the weight per unit volume of freshly mixed concrete. This test aids in proportioning concrete mixtures and assessing the amount of aggregate, cement, and water present in the mix. It provides insights into the density and overall quality of the concrete.

Method:

A known volume of freshly mixed concrete is poured into a container.

The weight of the container and the concrete is measured.

The unit weight is calculated by dividing the weight of the concrete by its volume.

Bleeding Test

The bleeding test evaluates the tendency of water to segregate from the concrete mixture. Bleeding can lead to surface defects, reduced durability, and weakened concrete. The test involves allowing fresh concrete to settle and observing the water accumulation on the surface.

Method:

Freshly mixed concrete is placed in a container and allowed to sit undisturbed for a period of time.

Any water that accumulates on the surface of the concrete is observed and measured.

Bleeding can be assessed by the amount of water that has separated from the concrete mixture.

Setting Time Test

The setting time test determines the time it takes for concrete to change from a plastic to a solid state. Initial setting time is when the concrete can support light loads, while final setting time is when it becomes rigid. These times affect construction schedules and dictate the timing of finishing operations.

Method:

Initial setting time is determined using the Vicat apparatus. A needle is gently placed on the surface of the concrete, and the time at which the needle stops penetrating is recorded.

Final setting time is determined in a similar manner, but a larger needle is used, and the concrete is considered set when the needle no longer creates an impression.

Conclusion

Fresh concrete tests are essential tools for ensuring the quality and performance of concrete structures. By conducting these tests, engineers, contractors, and quality control professionals can make informed decisions, optimize mix designs, and prevent potential issues that may arise during construction and throughout the lifespan of the concrete.

Comments

Post a Comment